All too often i receive items that another sharpener “ruined” because it now runs too loud or it wont cut or it had too tight of tension so the groomer loosened it themselves. In all of these cases, everything is fixable. Understanding the issues may help you and your sharpener in the future. Communication is key!

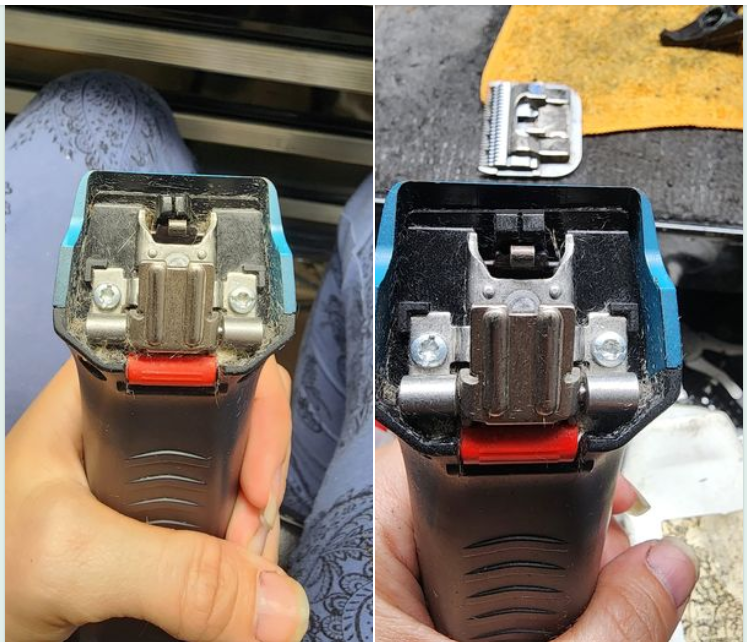

1. Noisy blades: if ALL of your blades are loud, im going to want to see your clipper to check the hinge and drive/lever. If ONE or A FEW are loud, im going to want to check out your blade sockets. My best advice to clients is to have a sharpie and put a dot or mark on the socket of blades that may be louder than others. While there are many reasons your blade may be loud, usually it is the socket or maybe a damaged blade guide. (See reference pic above.) If i see all of your loud blades are 7, 5, and 4 length, it could be you have a km cordless that needs a simple mod to properly hold the blade without knocking the housing. It is important to let us know blades are loud for you because it is possible they work great when we test them on our clippers.

2. Tension. I am so happy to see more groomers noticing when tension is too tight. I am NOT however thrilled by them correcting it by loosening the screws a little. This will result in injuries because loosening the screws allows the cutter to move freely. Many times, blades i am given that are too tight are actually unoiled or they are caked with residue from cooling sprays. Oil them! Dont loosen screws! If you loosen tension yourself by flexing back the cutter and blade spring, dont over do it. If tension is too loose, u will see lines in your grooms and having to force blades. (It sucks.) Have your sharpener check why you may be having tension issues. Some blade springs can be really stubborn.

3. Cutter placement on the comb. I have had groomers call back because the cutter is not aligned perfectly on the comb rails. Sometimes they dont align perfectly. We measure cutter placement based on where it sits on the blade comb teeth. Some groomers i see have tried assembling and disassembling blades on their own which is awesome to learn.. but i have seen some unfortunate cases where they break off all the teeth as soon as a guard comb is added due to incorrect placement lol. See pics below with captions

Blade sharpening is cool. I enjoy seeing those sparks flying, but there are so many considerations.. and it is common to see new customers who blame their old sharpeners for blades not working.. (heck i am sure i have been that groomer lol).. but there are faults to consider on your clippers (almost always hinge or blade drive) AND even if it is blade related, the blade may perform differently on your sharpener’s clippers. Putting a mark on the blade to let the sharpener know something is up is so helpful!

Also if you get fresh sharpening back and something isnt working right, let your sharpener know right away.. it allows us to note it and apply a credit or come back to fix asap. This is a lot like a client letting you know right away if they do not like a groom instead of waiting until the next groom is due and expecting it for free.. we all have to safeguard our businesses from scammers. (I learned this in suuuch a bad way after a groomer bragged about scamming me for free stuff. Im sensitive sooo i ugly cried.. it was just bad. Lol)

All reactions:

143Onaca Crawford – Stephens, Amber Bradley and 141 others